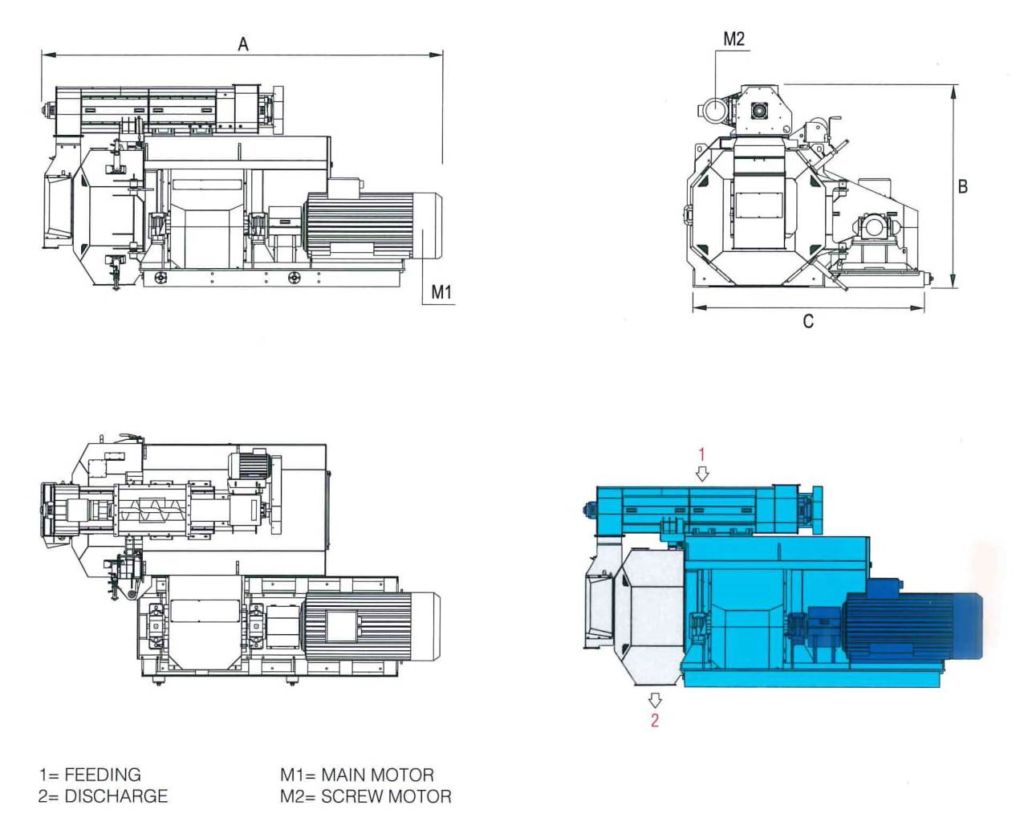

| Pellet mill Model | Diameter mm | Die width mm | Amm | Bmm | Cmm | Capacity – Cattle feedt/h | Capacity – Poultry feedt/h | Installed powerKw | Weight approx. Kg |

|---|---|---|---|---|---|---|---|---|---|

| PGPM300 | 300 | 90 | 1600 | 1640 | 1550 | 2,5 | 3,5 | 45-55 | 2500 |

| PGPM420 | 420 | 140 | 2050 | 2160 | 1850 | 6 | 8 | 90-110 | 5500 |

| PGPM520 | 520 | 178 | 3000 | 2300 | 1950 | 9 | 12 | 132-160-200 | 7500 |

| PGPM630 | 630 | 200 | 3275 | 2045 | 2045 | 12 | 18 | 160-200-250 | 9000 |

| PGPM750 | 750 | 250 | 4500 | 2245 | 2550 | 18 | 22 | 250-315 | 13000 |

| PGPM835 | 835 | 280 | 4500 | 2245 | 2750 | 20 | 25 | 250-315-355 | 16000 |

| PGPM950 | 950 | 300 | 4970 | 2525 | 2900 | 25 | 35 | 400-450 | 22000 |

| PGPM1200 | 1200 | 350 | 5400 | 2900 | 3500 | 32 | 50 | 500-560-630 | 32000 |

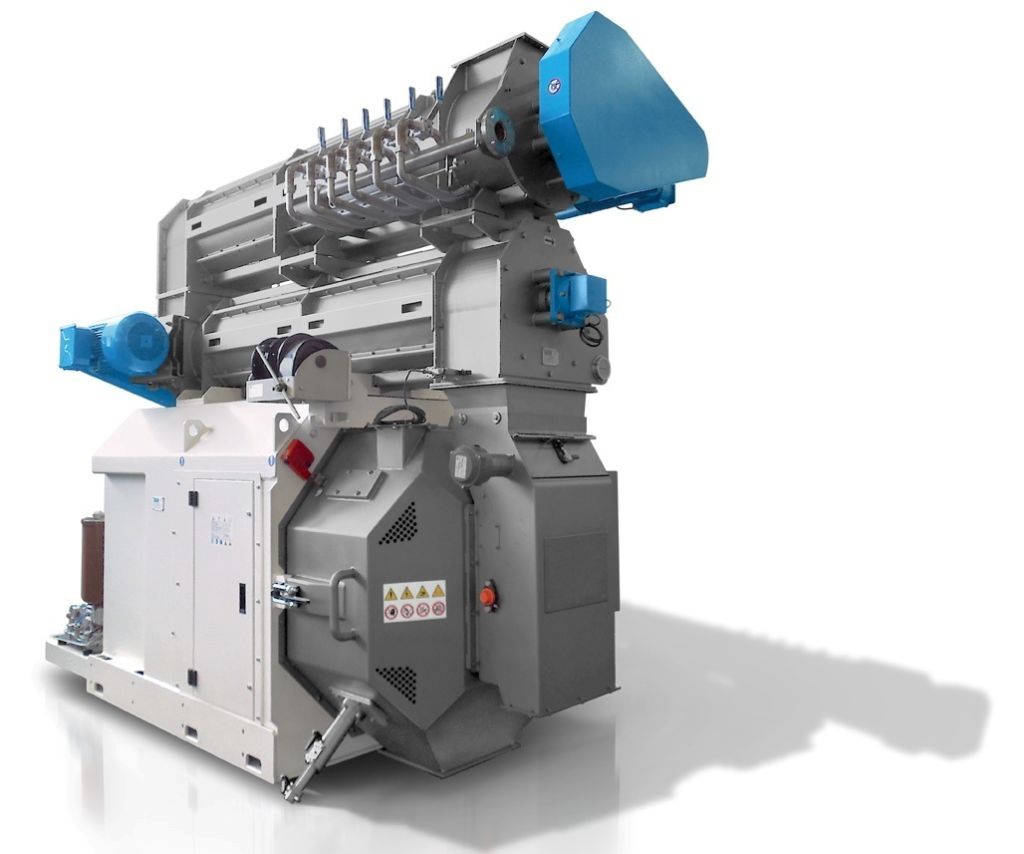

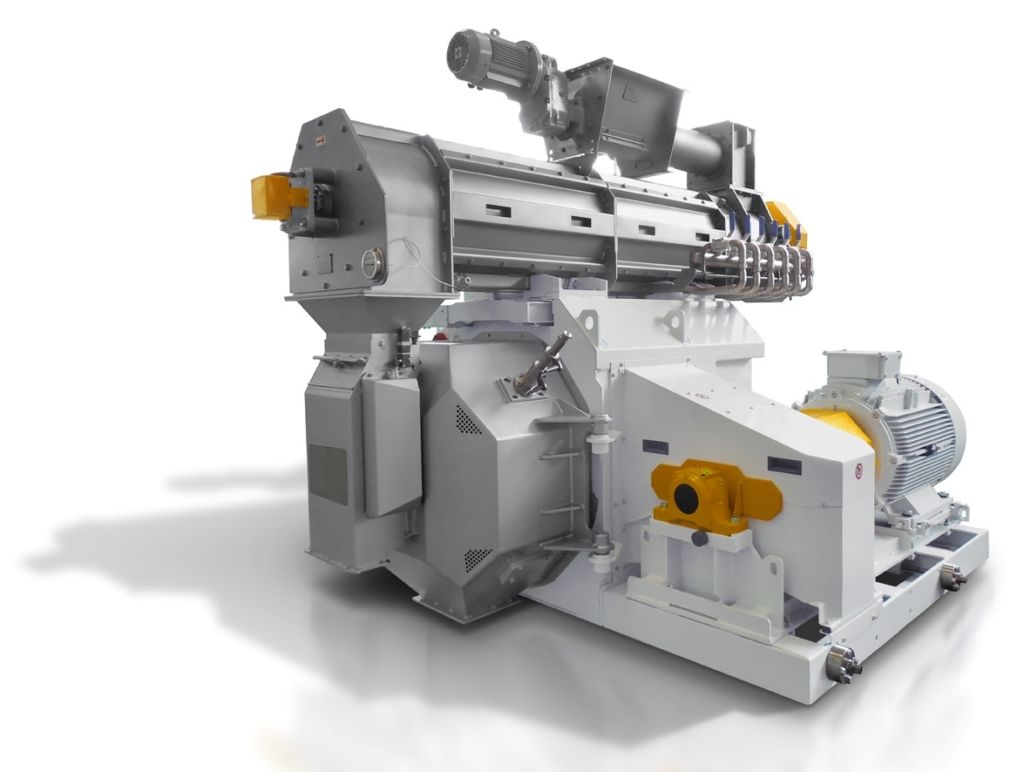

PGPM PELLET MILLS

TECHNICAL FEATURES OF PELLET MILLS

- Pellet mill die diameter from 300 mm to 1200 mm

- Main structure of pellet mill made of considerably thick steel

- Drive pulley installed on a countershaft between two separate supports, coupled to the main motor by an elastic—block coupling

- Pellet mills door entirely made of inox AISI 304 stainless steel, with two knives

- Feed chute made of inox AISI 304 stainless steel with a choke with quick dump controlled by a pneumatic cylinder

- A permanent magnet is fitted in the chute to prevent ferrous metal from entering the die

- Rotor group made of a die holder mounted on the main shaft by means of two bearings able to withstand high workloads and high temperature

- Segmented die clamp makes bolt alignment easy, and facilities fast die change

- Main shaft mounted on the base by means of bronze bushings

- Bearing lubrication is guaranteed by an internal circuit that also works when the machine is working

- Pellet mill is driven by an electric motor via a V-belt transmission.

Category

PelletingDownload Documentation

The documentation of the Pellet mill machine is not available.

Request the technical data sheet and the documentation for this machine by filling out the form below.

You may interest:

CM conditioner for pelleting

View machineStatic cooler

View machineCrumbling Roller Mill

View machineDo you want more information?

If you need more details for the machine Pellet mill do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.