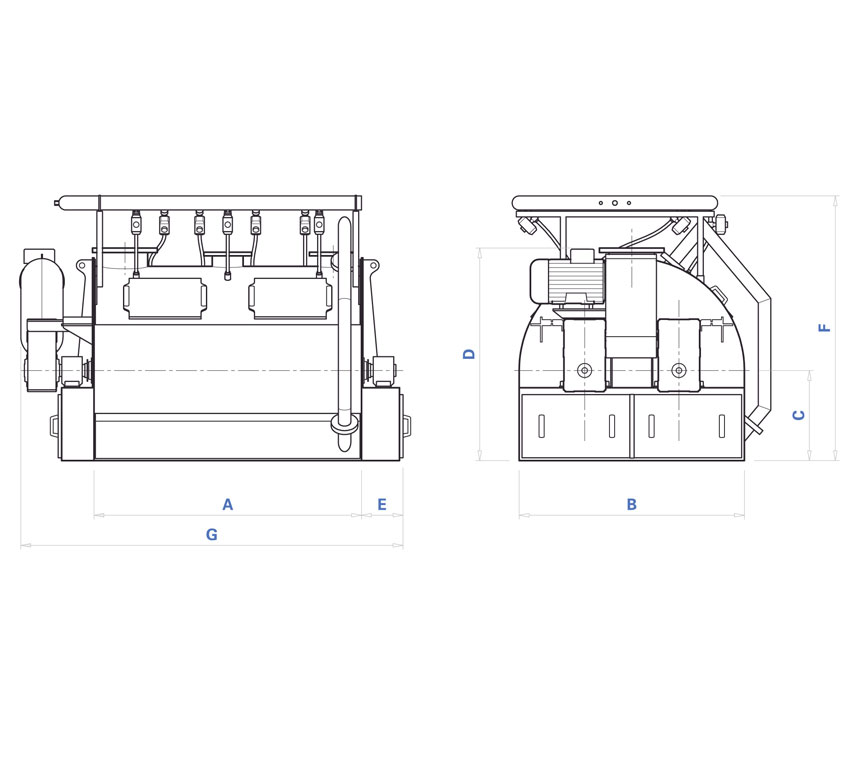

| Model | A | B | C | D | E | F | G | Usable Volume [m³] | Power [kw] | [Rpm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MO2-5P DV | 1900 | 1600 | 640 | 1510 | 295 | 1880 | 2715 | 1,4 | 11 | 38 | 2570 |

| MO2-8P DV | 2350 | 1780 | 700 | 1660 | 295 | 2010 | 3340 | 2,5 | 15 | 37 | 3340 |

The vacuum coater mixers are made of stainless steel 304 and are equipped with vacuum pump and heated body.

They are suitable for the addition of high percentage liquids on extruded products. They are used in pet-food, aqua-feed and feed industries.

They are available in sizes from 1400 to 2500 liters, but can be designed to meet specific customer requirements.

MIXING CAPACITY

The particular design of the paddles enables this machine to consistently achieve a high standard of homogeneity of the mixture. A mixing ratio of 1:100,000, coefficient of variation (CV) <3%.

ADDING LIQUID

In producing feed, it is possible to add liquid up to an amount equal to 25%.

The liquid reaches the core of the pellet and of the extruded product through the vacuum process.

MIXING TIME AND DISCHARGE TIME

Mixing time, depending on the type of material, is very rapid, also in the case in which the mixer is not under full load, mixing time is not slowed down due to the particular design of the paddles.

– Mixing time: 60 seconds starting from the addition of the last amount of any additive, whether solid or liquid.

– Discharge time of the mixer is about 10-15 seconds.

– The mixing plant can work 20 lots/h, totally automatic.

Discharge is extremely rapid due to the doors along the entire length of the machine.

OPTIMAL CLEANING

Total discharge of the product is guaranteed by doors along the entire length of the machine.

LOW MAINTENANCE

The rational and robust construction, the large size of all of the components, the ease of inspecting the tank and the shaft through special hatches, make our horizontal mixer extremely reliable.

Category

CoatingDownload Documentation

You may interest:

Single shaft vacuum coater mixer

View machineDo you want more information?

If you need more details for the machine Vacuum coater mixer do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.