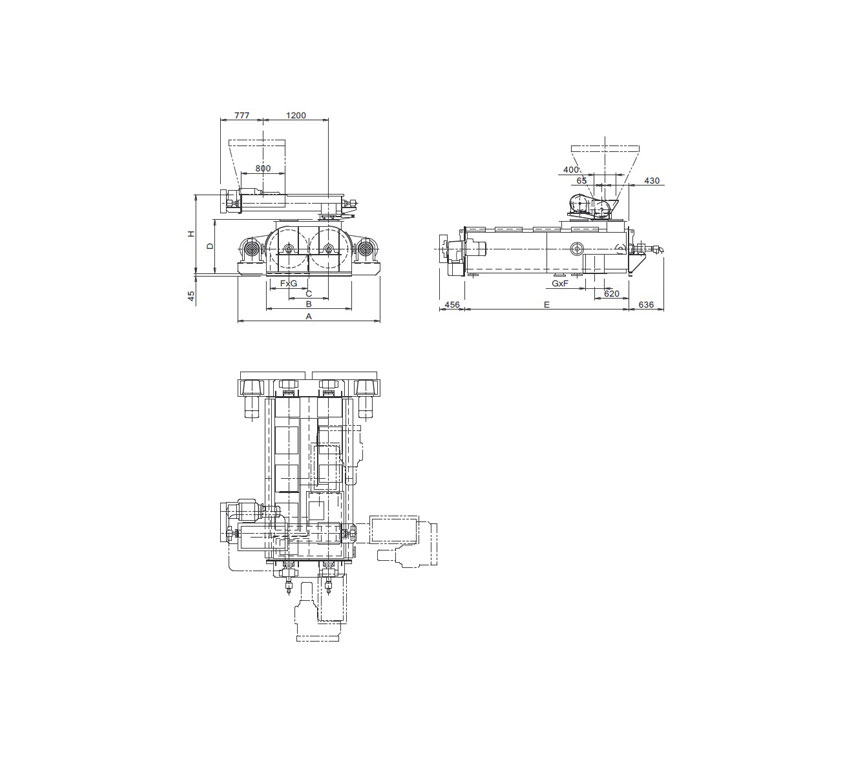

| Model | A | B | C | D | E | F | G | H | Capacity [Ton/h] | Useful Volume [m³] | Power [kw] | Residence time of the product [min] | Weight[kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSR8/30 | 2800 | 1760 | 830 | 1080 | 3000 | 800 | 350 | 1603 | 27 | 2,1 | 11×2 | 2,5 | 3200 |

| CSR7/30 | 2600 | 1560 | 730 | 988 | 3000 | 700 | 350 | 1443 | 20 | 1,6 | 7,5×2 | 2,6 | 2950 |

| CSR6/30 | 2500 | 1360 | 630 | 888 | 3000 | 600 | 350 | 1343 | 15 | 1,2 | 7,5×2 | 2,6 | 2750 |

| CSR5/30 | 2400 | 1160 | 530 | 788 | 3000 | 500 | 350 | 1183 | 10 | 0,8 | 5,5×2 | 2,6 | 2600 |

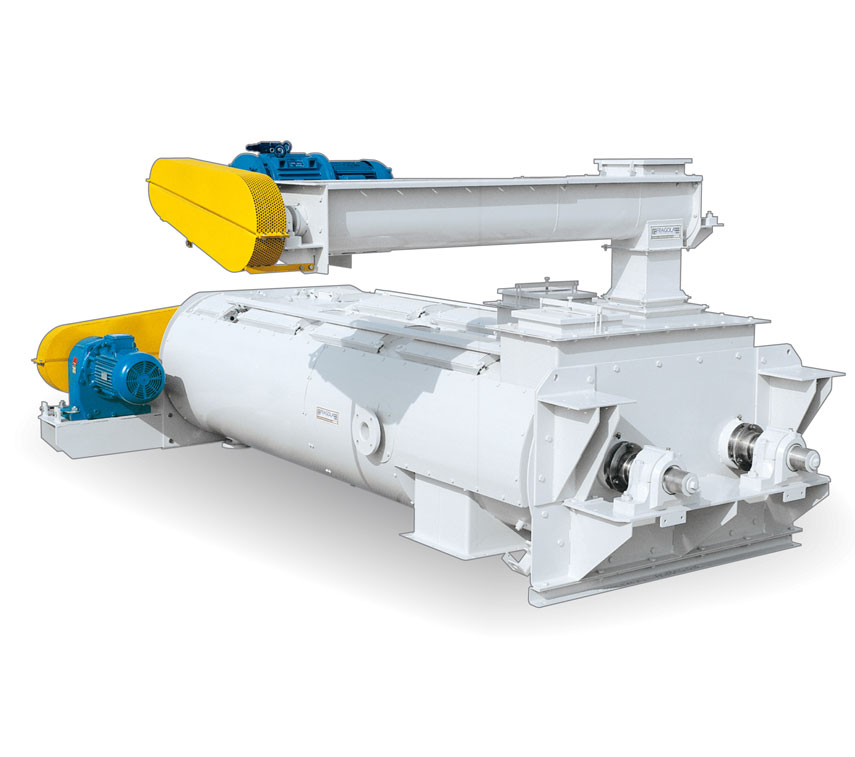

Benefits of thermal treatment and sanitation in animal feed production

– Removal of pathogenic organisms: under certain conditions of time and temperature, destruction of salmonella and other bacteria.

– Increase in the preservation of the feed thus treated.

– Increase in the digestibility of the feed and the conversion factor on the farm.

– Increase in the quality and durability of the pellet.

– Increase the productivity of the pellet mill.

FEATURES OF THE FRAGOLA DOUBLE SHAFT RECYCLING CONDITIONER

- The Fragola double shaft conditioner operates with direct steam, injected directly into the meal, and with the heat transferred from the body of the machine, also heated indirectly with steam.

- Increase in the productivity of the pellet mill from 5% to 15% with insertion of the Fragola conditioner.

- The amount of product entering the conditioner is controlled by a screw feeder.

- Discharge of product from the conditioner is made through a tubular screw which guarantees a constant and optimal load to the pellet mill.

- It is possible to work between 40°C and 95°C in function of the raw material to be treated and the presence of thermolable components, the times of treatment generally vary from 2 to 4 minutes.

- The machine is made of stainless steel AISI 304.

- The paddles are bolted and adjustable.

Category

Conditioning and pelletingDownload Documentation

Do you want more information?

If you need more details for the machine Double shaft recycling conditioner do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.