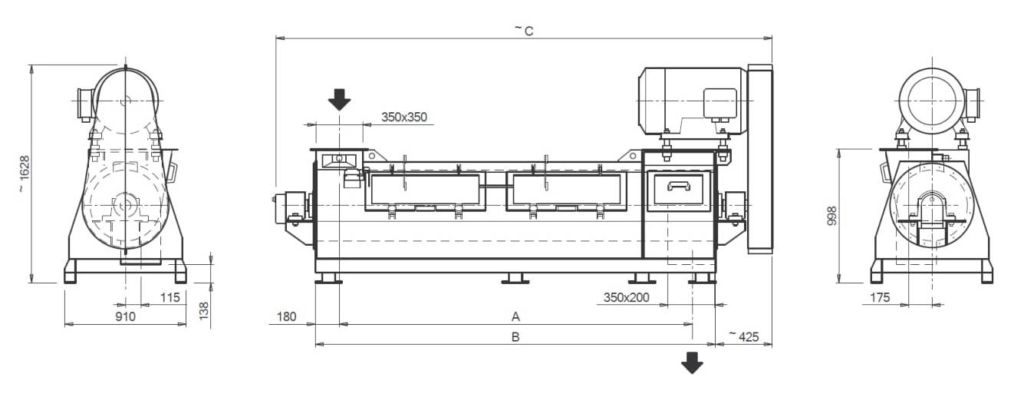

| Model | A | B | C | Potentiality [ton/h]* | Power [Kw] | Rpm | Weight [Kg] |

|---|---|---|---|---|---|---|---|

| MCF5/20 | 1645 | 2000 | 2700 | 30 | 37 | 550 | 1520 |

| MCF5/25 | 2145 | 2500 | 3220 | 50÷70 | 45 | 540 | 1670 |

| MCF5/30 | 2645 | 3000 | 3720 | 70÷100 | 55 | 540 | 1820 |

(*) SPECIFIC WEIGHT OF THE PRODUCT: 0,6 t/m3

CONTINUOUS MIXER

The MCF Continuous Mixer, in feed sector known as ‘Mixer for addition of molasses’, is capable of optimally distributing a liquid, such as molasses, oil, or a mixture of oils, into a flow of flour.

Models are available with capacities from 10 to 100 ton/h.

CHARACTERISTICS OF THE MCF CONTINUOUS MIXER

- Constructed in AISI 304 stainless steel in all parts which are in contact with the product.

- Tank comes complete with an integrated heating system.

- Tank is insulated to prevent heat loss or heat exchange with the external environment.

- Shaft features bolted and adjustable shaft blades.

LIQUID INJECTION INTO THE CONTINUOUS MIXER

The shaft design allows the introduction of liquids from 0.5 % to 15 %

The liquid is introduced into the continuous mixer through a pump, that is equipped with a flow meter which measures and records the quantity for comparison to the quantity of flour entering.

RELIABILITY AND LOW MAINTENANCE

- Functional and robust construction

- Large scale dimension of all components

- Easy access for inspection of the tank and shaft through special doors

Category

MixingDownload Documentation

You may interest:

Single shaft horizontal mixer

View machineDouble Shaft Horizontal Mixer

View machineSynchronized Shafts Mixer

View machineDo you want more information?

If you need more details for the machine Continuous mixer do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.