VIBRATING SCREEN

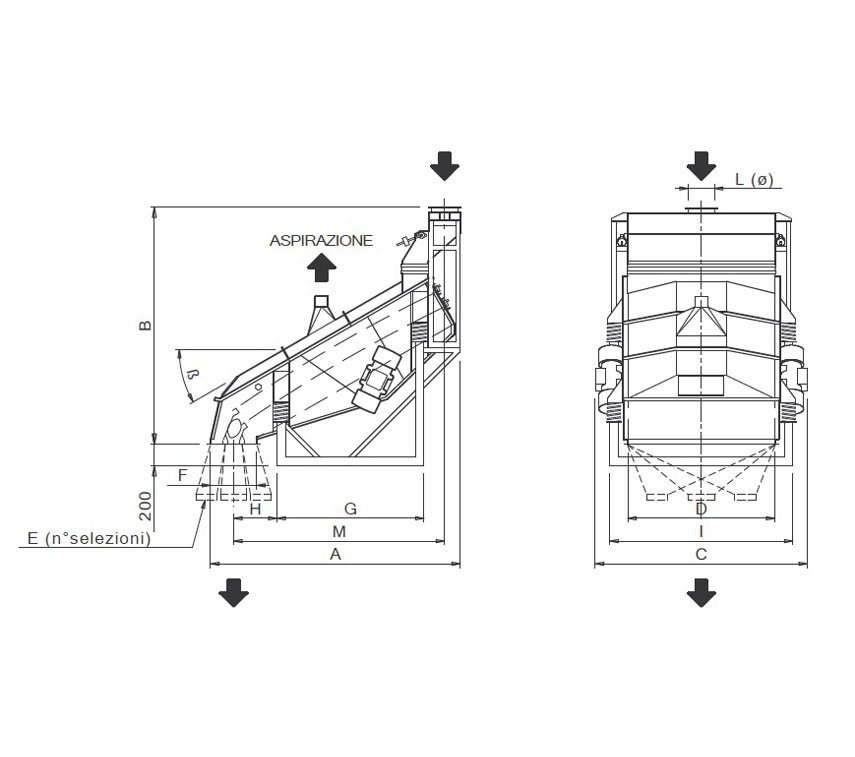

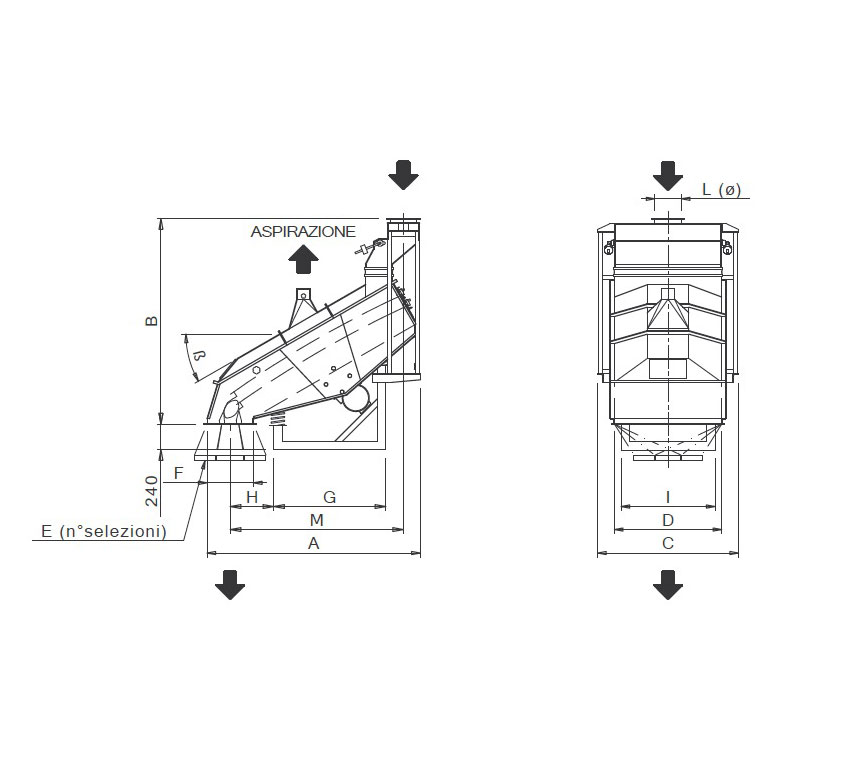

Our vibrating screens can be employed in the processing of granular and powdered products of various types and sizes. They have a special application in food manufacturing, for the cleaning of raw materia!, for the separation and screening of fiours from other products, particularly in the milling stage, for the cleaning and selection of pelleted and crumbled products. They are employed in the extraction industry for the grading Of sand, gravel, etc. Their very strong construction, the improvements made in the course of time, and the easy replacement of sieves, contribute to the high reliability and efficiency of this machine. The body is wholly reinforced and made of hot-drawn bolted elements of press-bent sheet. It rests on the support frame by means of iron springs, and this arrangement eliminates the transmission of vibrations to the screen housing level. The motor-vibrators are fastened to the body and to a draw piece connecting the block. Sieves are made of music wire grid, anchored on the head and stretched by tail tie rods. The adjustment of sieves, as well as their easy and quick replacement, is carried out externally. The screens can contain 1, 2 or 3 sieves in order to obtain 2, 3 or 4 different gradings of the product respectively. To increase the produttive capacity of a screen, 2 equal-mesh sieves can be assembled in parallel, with an intermediate grading bottom, thus obtaining 2 fractions of product.