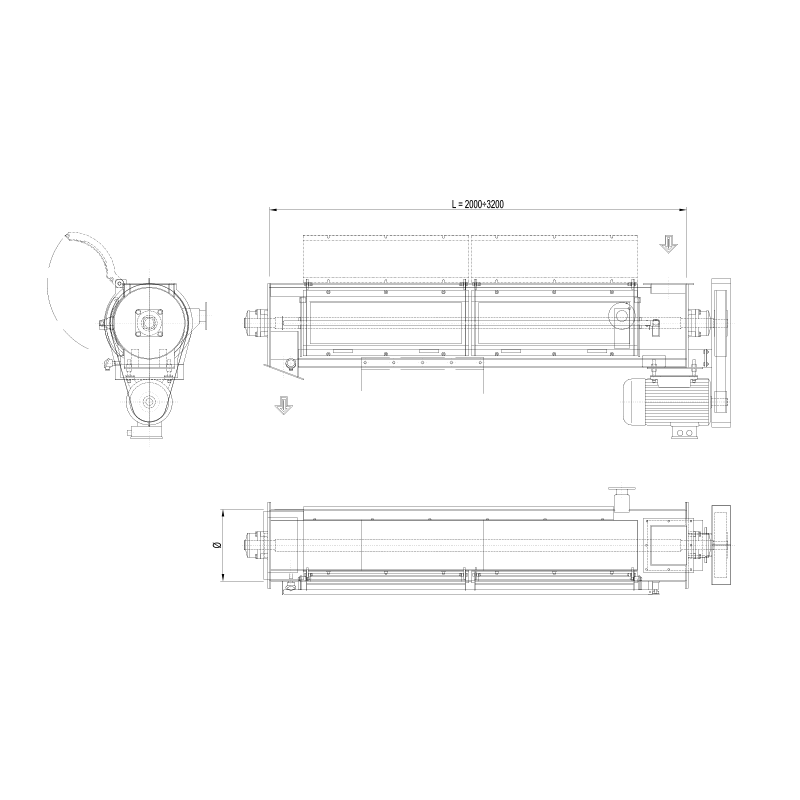

CS conditioner for pelleting

CS CONDITIONER – MEDIUM-TERM TREATMENT

The CS model conditioner, which is widely used in the FEED industry, allows up to one minute treatment of the flour to obtain a highly durable pellet and increased productivity of the pellet mill.

It provides the pellet feed with excellent starch gelatinisation and good pathogen abatement.