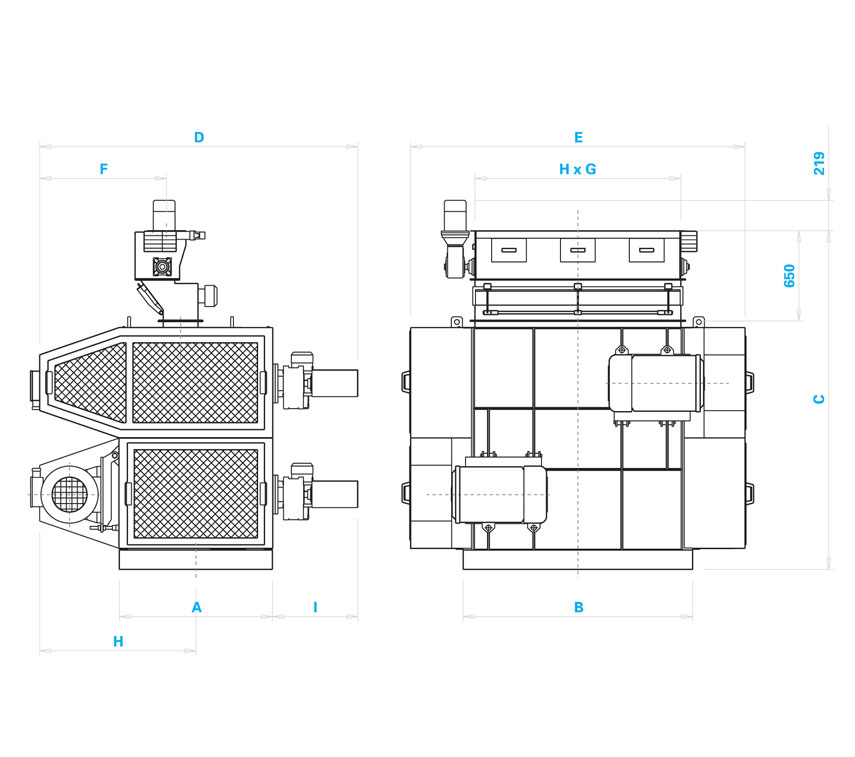

| Model | A | B | C | D | E | F | G | H | I | Cylindres n°4 ØxL [mm] |

Power [kw] | Capacity [ton/h] |

Average Granulometry [μm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LD 25/10 | 660 | 1130 | 1753 | 1952 | 1600 | 675 | 200 | 980 | 845 | 250×1000 | 15 + 15 | 10 ÷ 15 | 1500 ÷ 3500 | 3850 |

| LD 25/15 | 660 | 1630 | 1753 | 1952 | 2100 | 675 | 200 | 1480 | 845 | 250×1500 | 22 + 22 | 15 ÷ 22 | 1500 ÷ 3500 | 4700 |

| LD 30/10 | 1100 | 1150 | 2440 | 2290 | 1905 | 912 | 200 | 980 | 615 | 300×1000 | 30 + 30 | 25 ÷ 35 | 1500 ÷ 3500 | 5050 |

| LD 30/15 | 1100 | 1650 | 2440 | 2290 | 2405 | 912 | 200 | 1480 | 615 | 300×1500 | 37+ 37 | 35 ÷ 55 | 1500 ÷ 3500 | 6100 |

- Motorized feeder fitted with rotor for product dosage.

- Permanent magnets device for foreign metallic bodies capture, located at mill inlet at the base of the feeder.

- Four rollers distance adjustment by servomotor, accuracy of positioning within tenth of a millimeter.

- Cast iron rollers thermally treated centrifugal, diameter mm.250 and mm.300.

- Rollers rifling customized for every exigencies varying rifling’s pitch and slope

- Differentiated rollers speed.

- Inspection and maintenance easy access

Category

Grinding with roller millDownload Documentation

Do you want more information?

If you need more details for the machine Four Roller Mill do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.