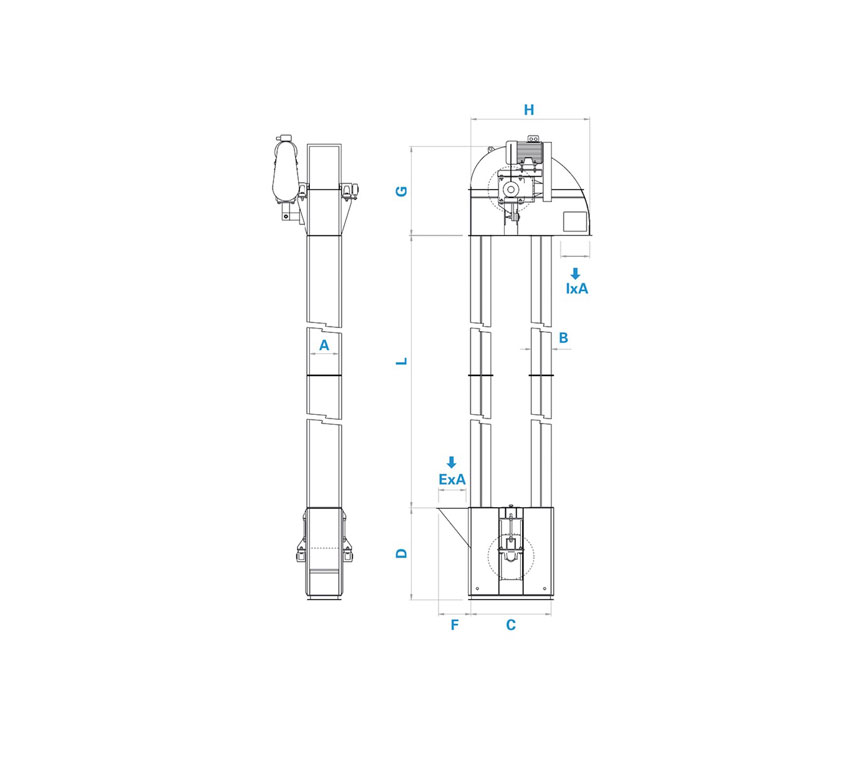

| Model | A | B | C | D | E | F | G | H | I | Potentiality** [m³/h] | Weight* [Kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ET750 D1000 | 750 | 350 | 1600 | 1800 | 500 | 600 | 2010 | 2300 | 600 | 220 ÷ 400 | 3.200 + 90 Kg/m |

| ET500 D1000 | 500 | 350 | 1600 | 1600 | 500 | 600 | 2010 | 2300 | 600 | 140 ÷ 233 | 2.100 + 60 Kg/m |

| ET400 D700 | 400 | 300 | 1200 | 1400 | 400 | 460 | 1400 | 1800 | 500 | 90 ÷ 170 | 1000 + 42 Kg/m |

| ET360 D500 | 360 | 280 | 1000 | 1100 | 350 | 410 | 1130 | 1460 | 360 | 58 ÷ 100 | 565 + 33 Kg/m |

| ET320 D500 | 320 | 220 | 880 | 1000 | 300 | 350 | 970 | 1300 | 320 | 36 ÷ 85 | 470 + 28 Kg/m |

| ET260 D400 | 260 | 220 | 780 | 1000 | 260 | 310 | 870 | 1140 | 260 | 26 ÷ 62 | 300 + 21 Kg/m |

| ET220 D400 | 220 | 220 | 780 | 1000 | 260 | 310 | 870 | 1140 | 260 | 9 ÷ 30 | 270 + 16 Kg/m |

| ET160 D250 | 160 | 160 | 510 | 700 | 160 | 210 | 505 | 735 | 160 | 60 | 140 + 12 Kg/m |

** Potentiality calculated with a speed of 2,5 m/s

* Weight not including motor

Large-sized in all its parts and constructed strongly and rationally, this is a machine suitable for enduring the heaviest operating conditions. Special hatches and removable parts situated in the crucial spots of the conveyance course facilitate inspection and any necessary maintenance. Both gearcases are constructed with bolted elements and are equipped with interchangeable loading and unloading wear plates. The shafts are supported by plummer block housing-bearing. The pulleys may have a simple lathe-turned continuous sheet metal covering, be sheathed in rubber, or be caged, depending on the operating conditions.

The transfer case may be equipped with a cradle to prevent cross-contamination, reducing the residues of the materials conveyed. The shape of the buckets and materials used also depend on the operating conditions. The motor may have parallel-axis or orthogonal-axis reduction gears, with the slow hollow shaft splined directly to the machine shaft, or else equipped with a flexible coupling between the reduction gear and the machine. The materials used are usually carbon steel or stainless steel. It comes complete with accessory devices for its installation to standard.

Category

Reception and handlingDownload Documentation

You may interest:

Screw Conveyor

View machineChain Conveyor

View machinePaddle Conveyor

View machineDo you want more information?

If you need more details for the machine Bucket Elevator do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.