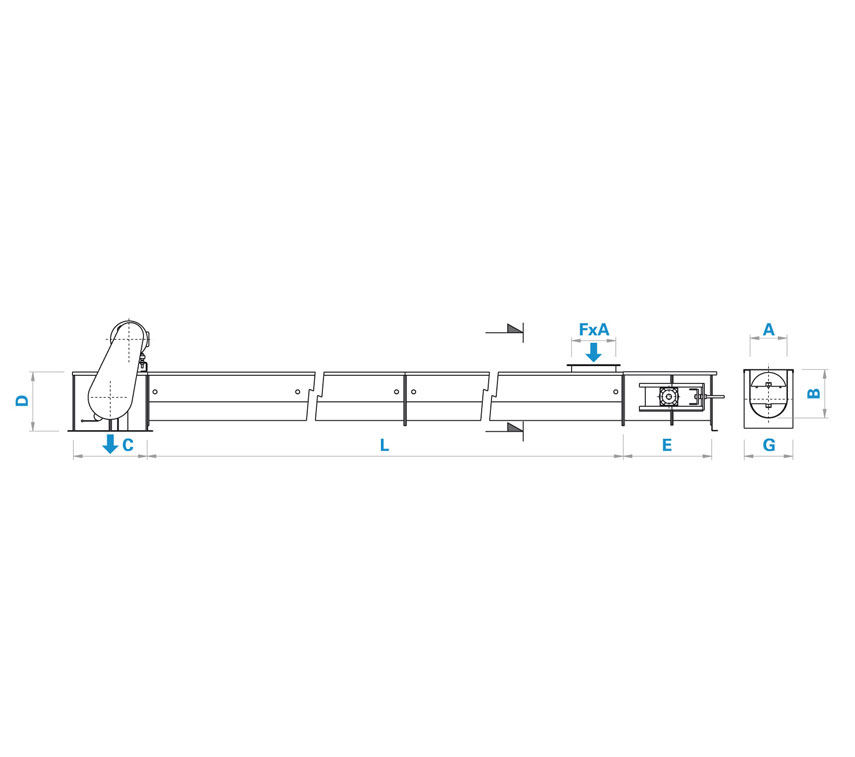

| Model | A | B | C | D | E | F | G | potentiality [m³/h] | Weight* [Kg] |

|---|---|---|---|---|---|---|---|---|---|

| TP47 | 470 | 565 | 750 | 610 | 900 | 450 | 570 | 124 | 355 + 55 Kg/m |

| TP37 | 370 | 460 | 60 | 530 | 850 | 400 | 457 | 85 | 327+43 Kg/m |

| TP32 | 320 | 425 | 550 | 465 | 750 | 350 | 408 | 57 | 292 + 43 Kg/m |

| TP25 | 250 | 330 | 500 | 400 | 600 | 300 | 337 | 34 | 188 + 37 Kg/m |

| TP18 | 180 | 275 | 400 | 328 | 550 | 1900 | 260 | 17 | 165+30 Kg/m |

Particularly suitable for transporting delicate products which are free from any cross-contamination. The conveyor element consists of a series of special plastic paddles attached to a pulling chain. Their shape is such that they leave the trough they wipe through perfectly clean. The gearcases are flanged to the casing and constructed in sections around the shafts, so that they can be easily and quickly disassembled. The gearbox contains an anti-clogging device.

The shafts are usually supported by plummer block housing-bearing. The casing is of strong press-bent sheet metal. The motor may have parallel-axis or orthogonal-axis reduction gears, with the slow hollow shaft splined directly to the machine shaft, or else equipped with a flexible coupling between the reduction gear and the machine. Construction is usually of carbon steel and stainless steel.

Category

Reception and handlingDownload Documentation

You may interest:

Chain Conveyor

View machineScrew Conveyor

View machineBucket Elevator

View machineDo you want more information?

If you need more details for the machine Paddle Conveyor do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.