ROTARY COOLER DRYER

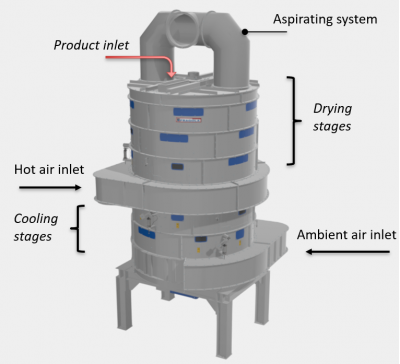

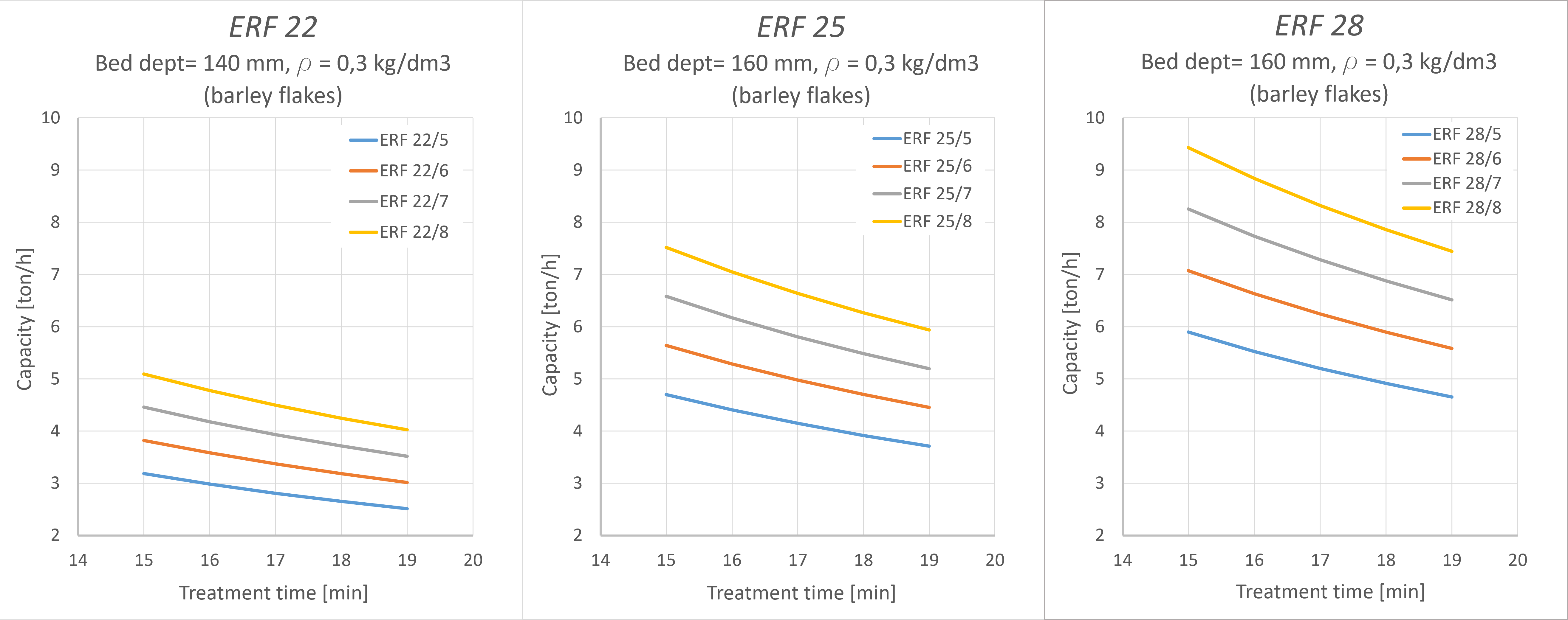

The ERF rotary dryer cooler is used in the drying and cooling of pellets, flour, flakes, coffee and cereals in general.

In the feed industry, it is used in the processing of pellets and cereal flakes.

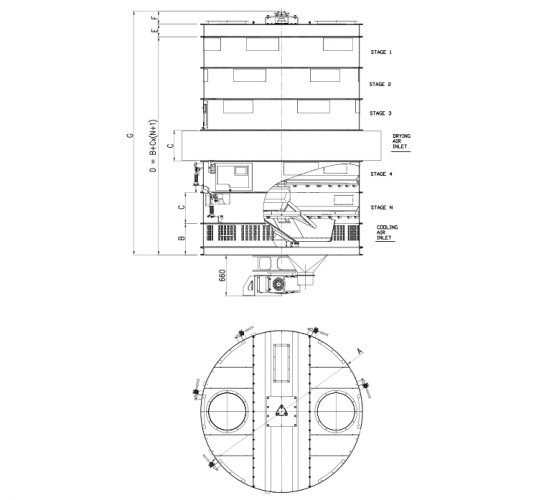

Thanks to their simple and rational design and robust construction, our modular rotary dryer-coolers are characterised by a high degree of reliability and efficiency.

In small installation spaces, they ensure optimal product handling in a short time.

STRENGTHS

- Effective and highly customisable process;

- Quick product change;

- High reliability;

- Low maintenance and access from outside to machine components;

- Easy installation in small spaces.