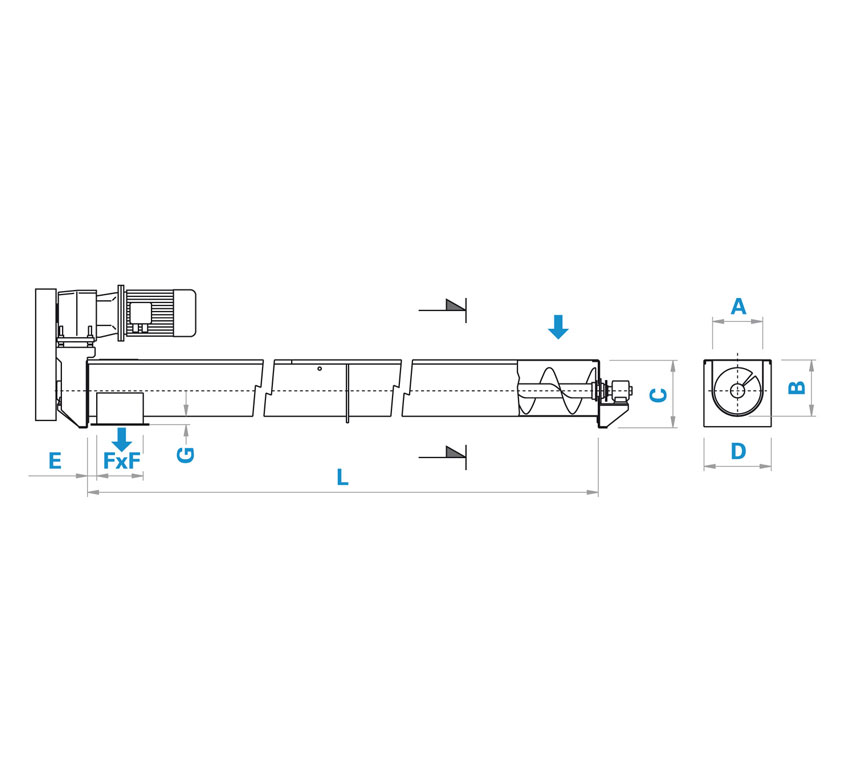

| Model | A | B | C | D | E | F | G | Potentiality [m³/h] | Weight* [Kg] |

|---|---|---|---|---|---|---|---|---|---|

| C500 | 520 | 565 | 640 | 620 | 70 | 500 | 50 | 200 | 930 |

| C400 | 420 | 465 | 540 | 510 | 60 | 400 | 50 | 133 | 720 |

| C350 | 370 | 405 | 465 | 450 | 50 | 350 | 50 | 93 | 620 |

| C300 | 320 | 355 | 415 | 400 | 50 | 300 | 50 | 60 | 460 |

| C250 | 270 | 305 | 365 | 350 | 50 | 250 | 50 | 40 | 380 |

| C200 | 220 | 255 | 310 | 290 | 50 | 200 | 50 | 24 | 300 |

| C160 | 180 | 215 | 270 | 250 | 50 | 160 | 50 | 16 | 250 |

*Weight: referring to a length of 10’000 mm. not including motor

Of simple, sturdy construction, this conveyor offers a high degree of reliability. The shaft is usually supported by plummer block housing-bearing at its extremities, and is equipped with dustproof seals. The middle supports are bushings of Teflon or other suitable material. he casing is constructed of flanged press-bent sheet metal, at the extremities of which the gearcases are also flanged. At the head of the conveyor is an anti-clogging device.

The motor may be either coaxial with a flexible coupling or with the slow hollow shaft reduction gear splined directly to the machine shaft. The casing and screw come in various versions, and may be of the continuous, paddle, or mixer type, depending on the various uses. When set up as an extractor, the auger may be a continuous screw with differentiated and progressive pitch, a combination of continuous screw and paddles, or with one or more axes. Construction is usually of carbon steel and stainless steel.

Category

Reception and handlingDownload Documentation

You may interest:

Chain Conveyor

View machinePaddle Conveyor

View machineBucket Elevator

View machineDo you want more information?

If you need more details for the machine Screw Conveyor do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.