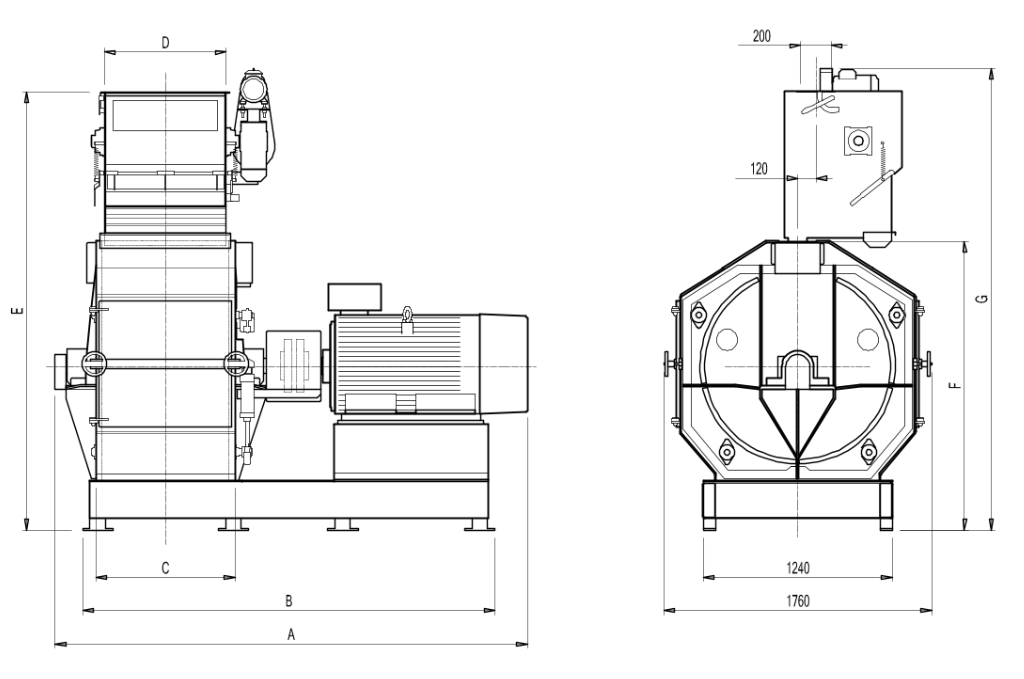

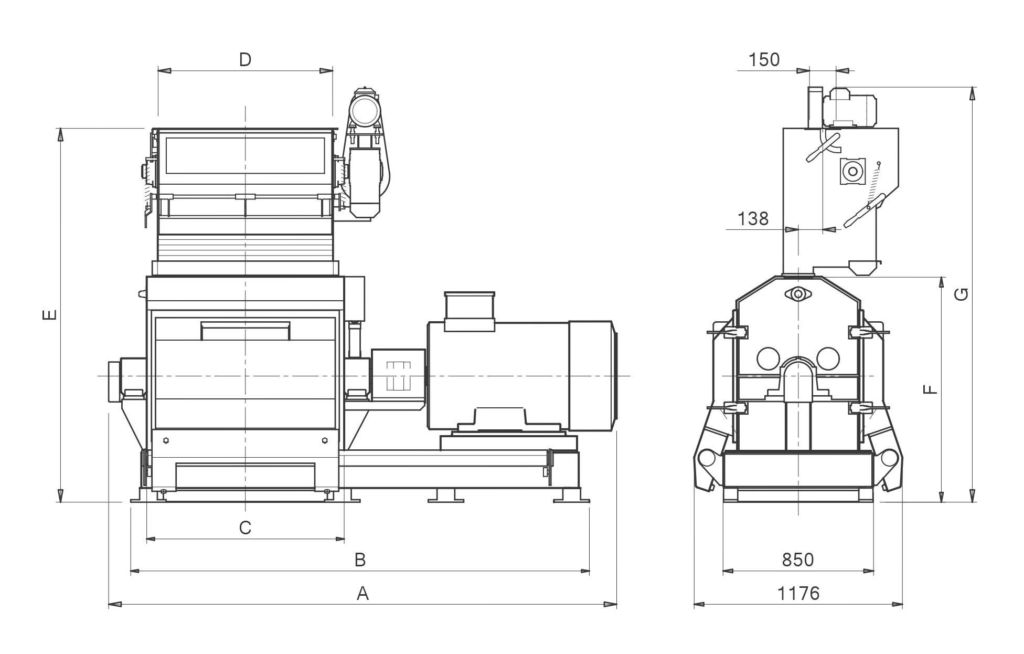

MF14D..G FRONTAL VERSION

| Model | A | B | C | D | E | F | G | Hammer n° | Screen surface m2 | Power Kw | Surface speed m/s | Rpm | Weight Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MF14 D13G + ASG4 | 2240 | 2180 | 470 | 360 | 2880 | 1900 | 3030 | 56 / 72 | 1.28 | 75 ÷110 | 87 | 1400 | 2350 |

| MF14 D20G + ASG6 | 2440 | 2415 | 690 | 580 | 2880 | 1900 | 3030 | 88 / 120 | 2.0 | 132 ÷160 | 87 | 1400 | 2650 |

| MF14 D27G + ASG8 | 3100 | 2750 | 910 | 800 | 2880 | 1900 | 3030 | 120 / 168 | 2.7 | 200 ÷ 250 | 87 | 1400 | 2950 |

| MF14 D33G + ASG10 | 3380 | 2925 | 1085 | 975 | 2880 | 1900 | 3030 | 152 / 216 | 3.3 | 250 ÷ 315 | 87 | 1400 | 3450 |

| MF14 D40G + ASG12 | 3801 | 3265 | 1325 | 1080 | 2944 | 1957 | 3129 | 184 / 264 | 4.0 | 315 ÷ 400 | 87 | 1400 | 4900 |

(*) WEIGHTS REFER TO MILL ONLY, WITHOUT ELECTRIC MOTOR AND ASG FEEDER-SEPARATOR

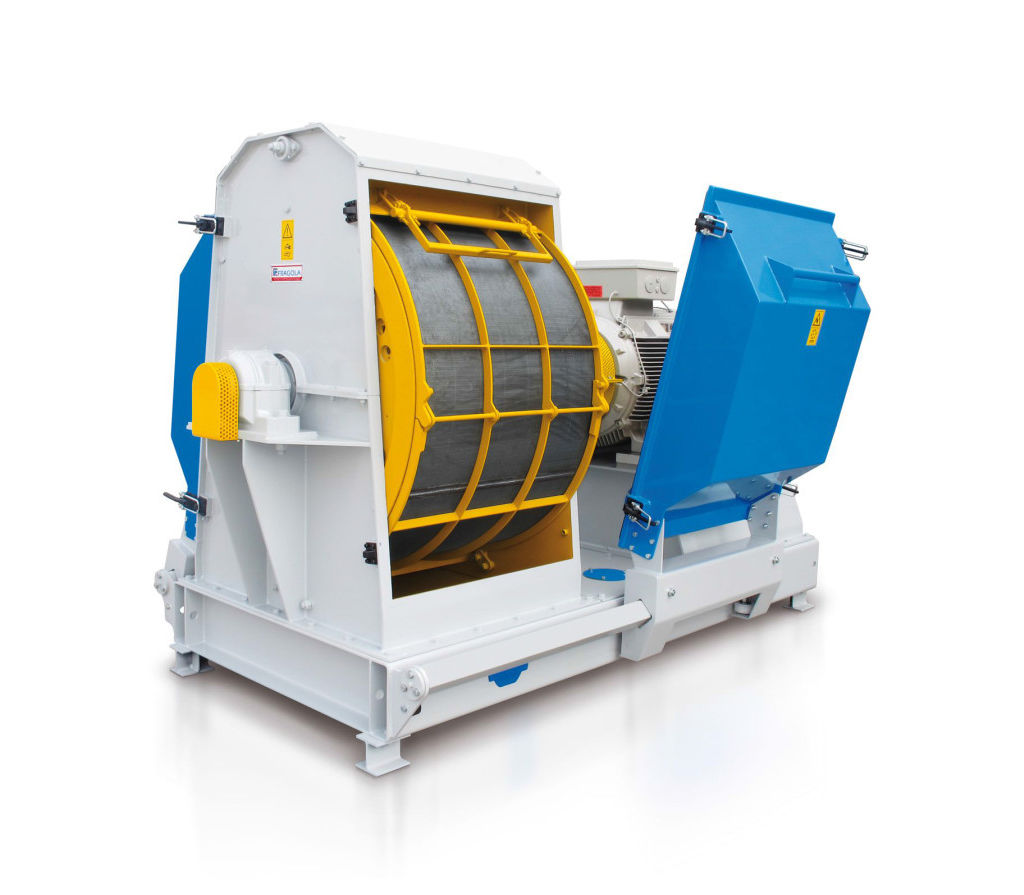

HAMMER MILL

In all models, whatever the installation power capacity may be, our hammer mill offers large sieving surfaces. The Fragola hammer mill consists of a monobloc base set on anti-vibration mounts and made of thick press-bent, electrically welded sheet steel. The body of mill is made of thick press-bent, welded sheet steel elements bolted together. The motor compartment base is also bolted to the monobloc base. Large side doors afford easy access to the inside of the grinding chamber. The upper shells of wearproof steel can be easily replaced from the outside thanks to their support, bolted to the machine body. When running, the our hammer mille is low-noise and has high stability, the latter characteristic being due to its sturdiness and the rotor, which is dynamically balanced at all speeds. The transmission between the motor and the shaft is by an elastic coupling. All models come in two versions, depending on the solution adopted for replacement of the sieves.

Model MF14D..G (frontal version): in our hammer mills the sieves consist of four pieces and can be replaced from the front, while the machine is running.

The sieves are locked in place by means of special pressure and containment frames which ensure simple, fast replacement.

The mill comes equipped with all safety devices required by current laws and regulations.

FEEDER

The feeder conveys the product into the grinding chamber of hammer mill , regulating the flow rate on the basis of the power draw of the mill’s motor. In addition to dosing the product, the feeder – with a honeycomb rotor and helical blades – also has a gravimetric device and exploits the suctioned air coming into the mill to perform the important function of separating any foreign bodies with different specific weights, such as iron pieces, stones, etc., from the product. Between the honeycomb rotor and the gravimetric device, as an additional safety measure, there is an easy-to-inspect magnet. The body is made of bolted elements and comes complete with a tray for collecting any foreign bodies.

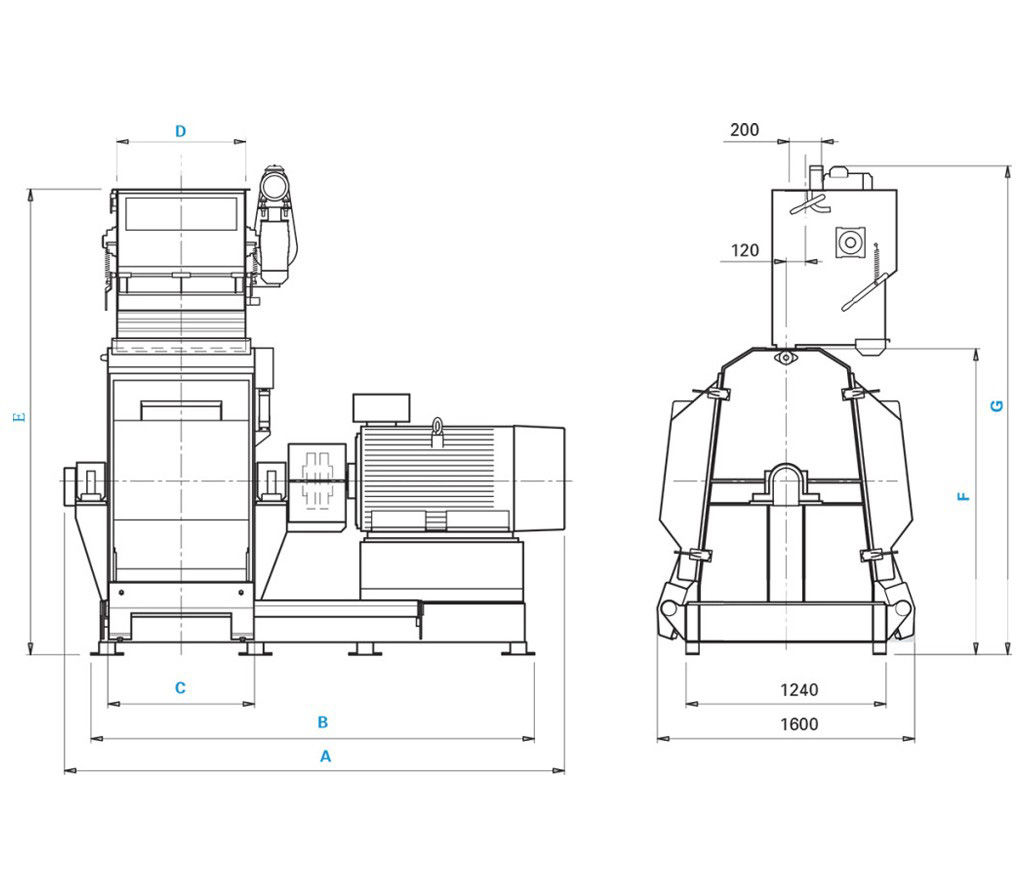

MF14D SIDE VERSION

| Model | A | B | C | D | E | F | G | Hammers n° | Screen surface m2 | Power Kw | Surface speed m/s | Rpm | Weight Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MF14 D13 + ASG4 | 2240 | 2180 | 470 | 360 | 2880 | 1900 | 3030 | 56 / 72 | 1.28 | 75 ÷110 | 87 | 1400 | 1700 |

| MF14 D20 + ASG6 | 2440 | 2415 | 690 | 580 | 2880 | 1900 | 3030 | 88 / 120 | 2.0 | 132 ÷160 | 87 | 1400 | 2200 |

| MF14 D27 + ASG8 | 3100 | 2750 | 910 | 800 | 2880 | 1900 | 3030 | 120 / 168 | 2.7 | 200 ÷ 250 | 87 | 1400 | 2700 |

| MF14 D33 + ASG10 | 3380 | 2925 | 1085 | 975 | 2880 | 1900 | 3030 | 152 / 216 | 3.3 | 250 ÷ 315 | 87 | 1400 | 3200 |

(*) WEIGHTS REFER TO MILL ONLY, WITHOUT ELECTRIC MOTOR AND ASG FEEDER-SEPARATOR

Model MF14D (side version): in our hammer mills the sieves consist of two pieces and can be replaced with the machine turned off, accessing them through the side doors which slide on two side runners.

The sieves are locked in place by means of special pressure and containment frames which ensure simple, fast replacement.

The machine comes equipped with all safety devices required by current laws and regulations.

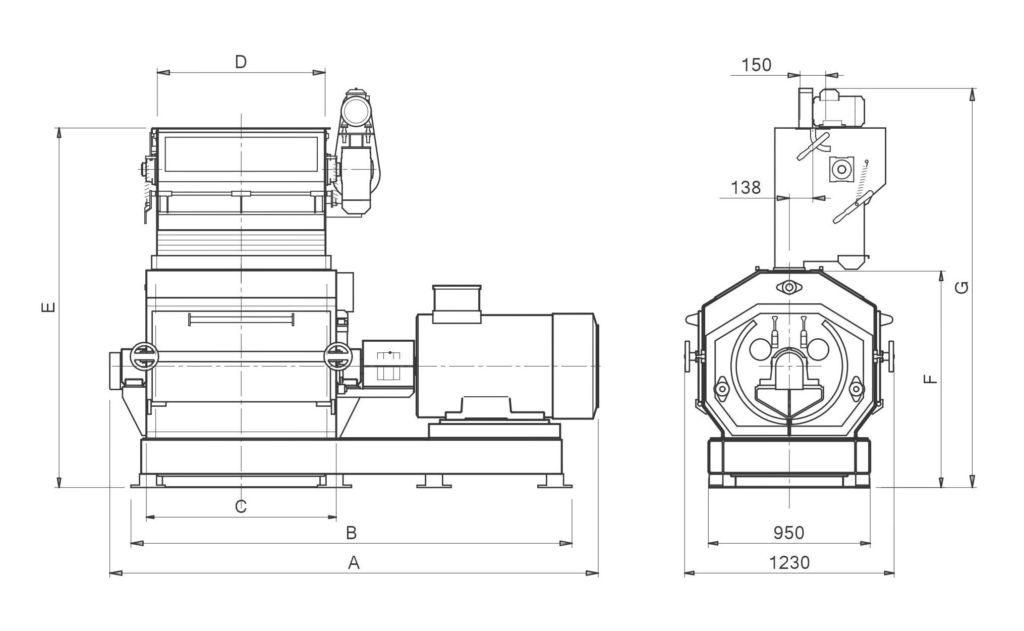

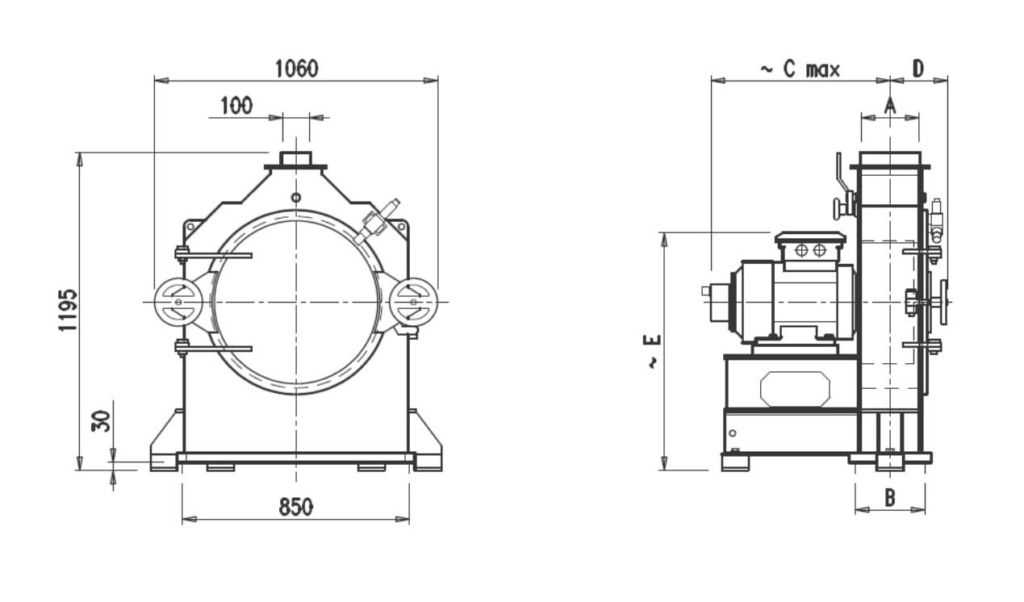

MF28D..G FRONTAL VERSION

| Model | A | B | C | D | E | F | G | Hammers [N°] |

Screen surface [m²] |

Power [kw] |

Surface speed [m/s] |

Rpm | Weight* [Kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MF28 D7 G ASG5R | 2050 | 2010 | 620 | 495 | 2390 | 1270 | 2340 | 52 | 0,7 | 37-75 | 92 | 2940 | 1610 |

| MF28 D10 G ASG7R | 2430 | 2210 | 820 | 600 | 2390 | 1270 | 2340 | 68 | 1,0 | 75-132 | 92 | 2940 | 1990 |

| MF28 D15 G ASG10R | 2870 | 2590 | 1115 | 890 | 2390 | 1270 | 2340 | 100 | 1,5 | 132-200 | 92 | 2940 | 2300 |

(*) WEIGHTS REFER TO MILL ONLY, WITHOUT ELECTRIC MOTOR AND ASG FEEDER-SEPARATOR

MF28D SIDE VERSION

| Model | A | B | C | D | E | F | G | Hammers [N°] |

Screen surface [m²] |

Power [kw] |

Surface speed [m/s] |

Rpm | Weight* [Kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MF28 D7 ASG5R | 2050 | 2010 | 620 | 495 | 2390 | 1270 | 2340 | 52 | 0,7 | 37-75 | 92 | 2940 | 1200 |

| MF28 D10 ASG7R | 2426 | 2210 | 820 | 600 | 2390 | 1270 | 2340 | 68 | 1,0 | 75-132 | 92 | 2940 | 1550 |

| MF28 D15 ASG10R | 2870 | 2590 | 1115 | 890 | 2390 | 1270 | 2340 | 100 | 1,5 | 132-200 | 92 | 2940 | 2000 |

(*) WEIGHTS REFER TO MILL ONLY, WITHOUT ELECTRIC MOTOR AND ASG FEEDER-SEPARATOR

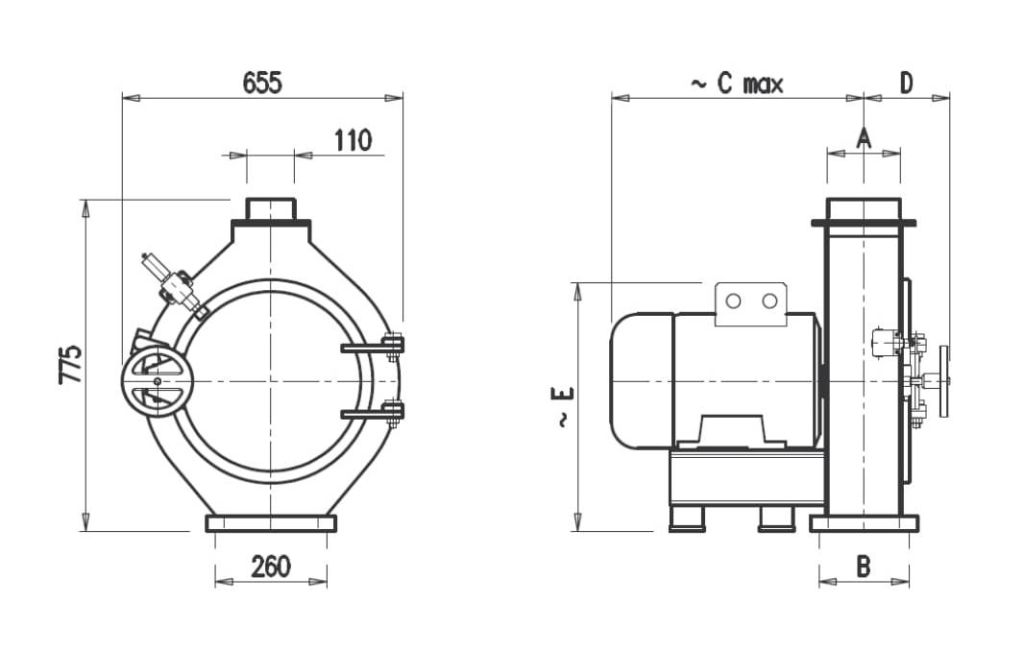

MF28 D300

| Model | A | B | C | D | E | Hammers N°. | Screen surface m² | Power Kw | Surface speed m/s | Rpm | Weight* Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MF28D300 | 215 | 260 | 670 | 215 | 893 | 18 | 0,3 | 15-30 | 91 | 2900 | 610 |

(*) WEIGHTS REFER TO MILL ONLY, WITHOUT ELECTRIC MOTOR AND ASG FEEDER-SEPARATOR

MF28D200

| Model | A | B | C | D | E | Hammers N°. | Screen surface m² | Power Kw | Surface speed m/s | rpm | Weight* Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MF28D200 | 170 | 210 | 590 | 200 | 580 | 12 | 0,2 | 11 | 57 | 2900 | 170 |

(*) WEIGHTS REFER TO MILL ONLY, WITHOUT ELECTRIC MOTOR AND ASG FEEDER-SEPARATOR

Category

Grinding with hammer millsQuick links

Model MF14D..G Big rotor hammer mill - Sieves replacement from the front, while the machine is running.Model MF14D Big rotor hammer mill - Sieves replacement from the sideModel MF28D..G Small rotor hammer mill - Sieves replacement from the front, while the machine is running.Model MF28D Small rotor hammer mill - Sieves replacement from the sideDownload Documentation

You may interest:

High Speed Hammer Mill

View machineVertical Mill

View machineFour Roller Mill

View machineDo you want more information?

If you need more details for the machine Hammer Mills do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.