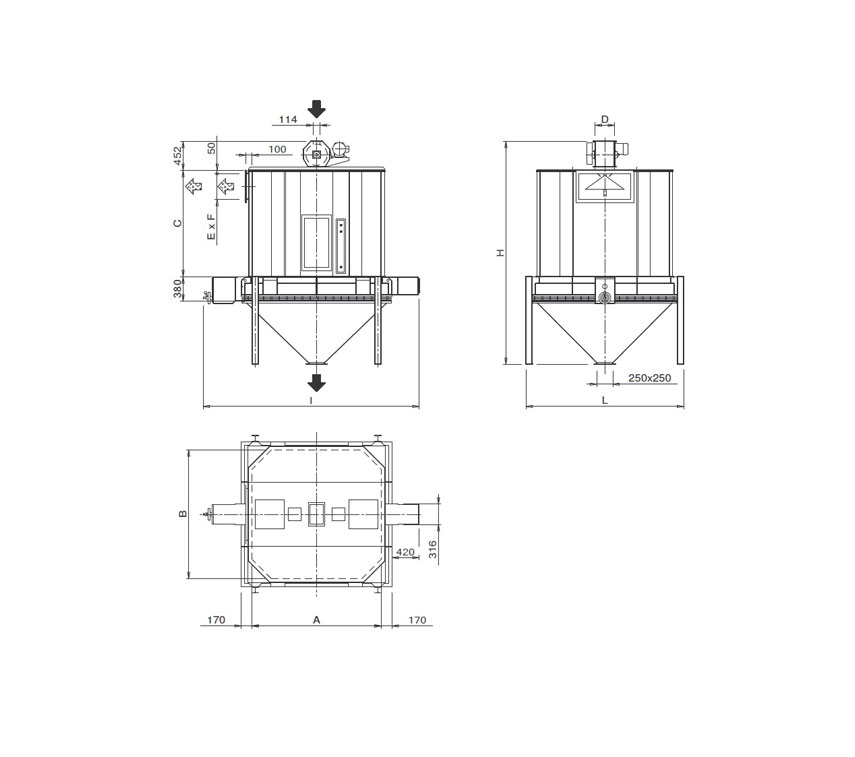

| Model | A | B | C | D | E | F | G | H | I | L | Volume m³ | Power ton/h |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RSF15 | 1520 | 1520 | 1390 | 300 | 300 | 600 | 750 | 2973 | 2870 | 1966 | 2,25 | 6,5 |

| RSF20 | 2000 | 2000 | 1650 | 300 | 400 | 800 | 950 | 3433 | 3350 | 2446 | 4 | 12 |

| RSF25 | 2480 | 2480 | 2000 | 550 | 500 | 1000 | 1150 | 3983 | 3830 | 2926 | 6,25 | 18 |

| RSF30 | 2960 | 2960 | 2300 | 550 | 600 | 1200 | 1350 | 4483 | 4310 | 3406 | 9 | 25 |

Fragola RSF Static Coolers are used for cooling pellets from the pellet mill and/or extruded product after the coating process, take the product to room temperature

Available capacity from 5 ton/hour to 50 tons/hour, specific gravity of 0.6 tons / m3.

OPERATION

The product is dosed into the cooler through a rotary feeder and is cooled by counterflow air flow. Cooling takes place gradually until the product is discharged into the collecting hopper.

Variousunloading systems are available to ensure product integrity.

Cooling time from 8 and 10 minutes.

Category

Cooling and dryingDownload Documentation

Do you want more information?

If you need more details for the machine Static cooler do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.