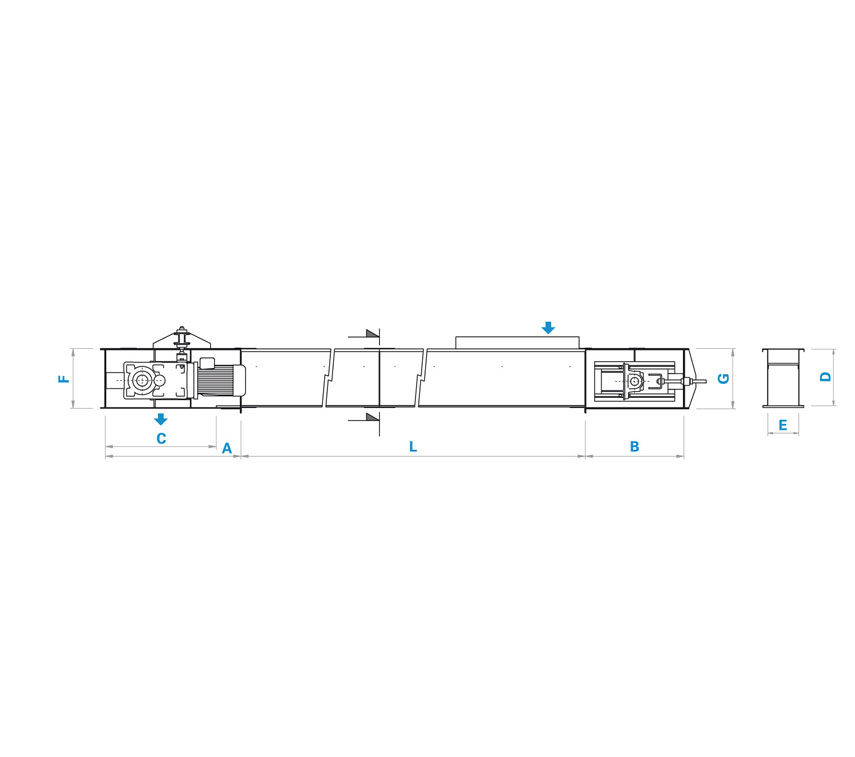

| Model | A | B | C | D | E | F | G | Potentiality [m³/h] | Weight* [Kg] |

|---|---|---|---|---|---|---|---|---|---|

| TC500H | 1.300 | 1.100 | 1.150 | 670 | 500 | 702 | 708 | 400 | 1.300 + 153 Kg/m |

| TC500N | 1.100 | 900 | 900 | 590 | 500 | 616 | 622 | 287 | 1.225 + 145 Kg/m |

| TC400H | 1.100 | 900 | 900 | 550 | 400 | 576 | 582 | 240 | 880 + 120 Kg/m |

| TC400N | 1.100 | 800 | 900 | 460 | 400 | 485 | 490 | 173 | 835 + 115 Kg/m |

| TC350N | 1.100 | 800 | 900 | 460 | 350 | 485 | 490 | 153 | 735 + 100 Kg/m |

| TC300N | 1.100 | 800 | 900 | 460 | 300 | 485 | 490 | 133 | 630 + 95 Kg/m |

| TC250N | 1.100 | 800 | 900 | 460 | 250 | 485 | 490 | 93 | 510 + 90 Kg/m |

| TC200N | 900 | 800 | 800 | 380 | 200 | 399 | 503 | 60 | 350 + 60 Kg/m |

* Weight not including motor