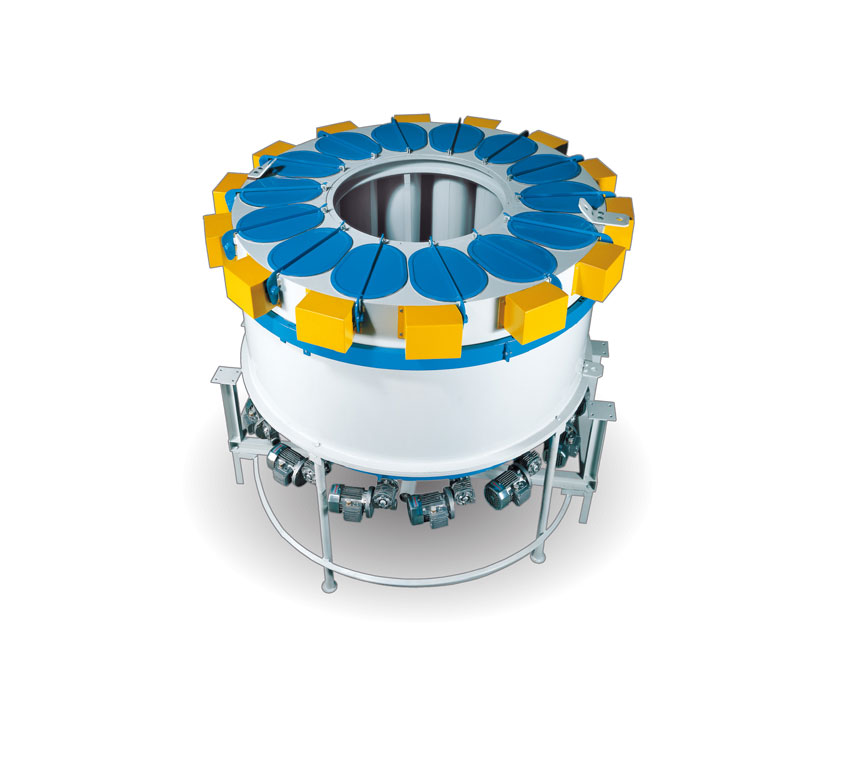

Micro ingredient dosing system

Dosage is an essential step in the production of premixes and micro ingredients.

Our micro ingredients / concentrates / additives dosing system has many advantages:

- Optimises time-consuming manual tasks resulting in productivity gain and elimination of human error.

- High precision dosing.

- High standards of cleanliness and precautions against cross-contamination.

THE PLANT CONSISTS OF:

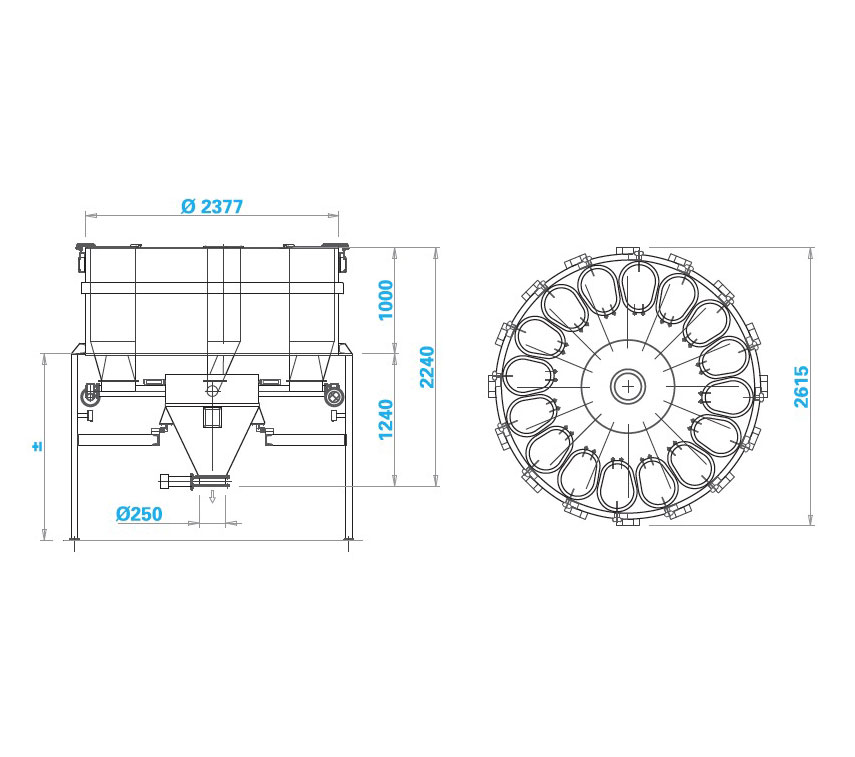

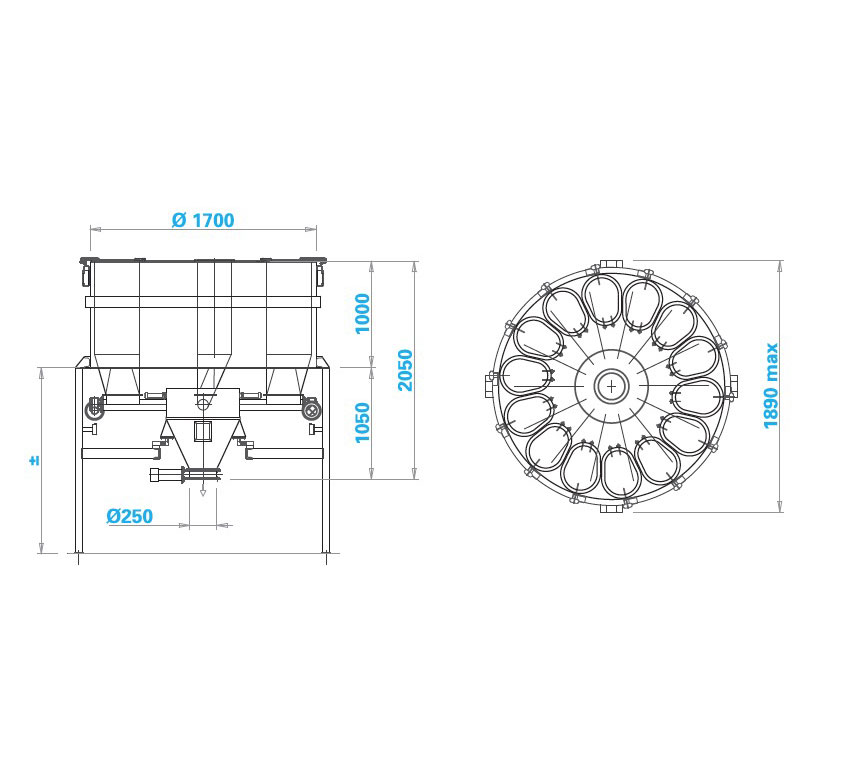

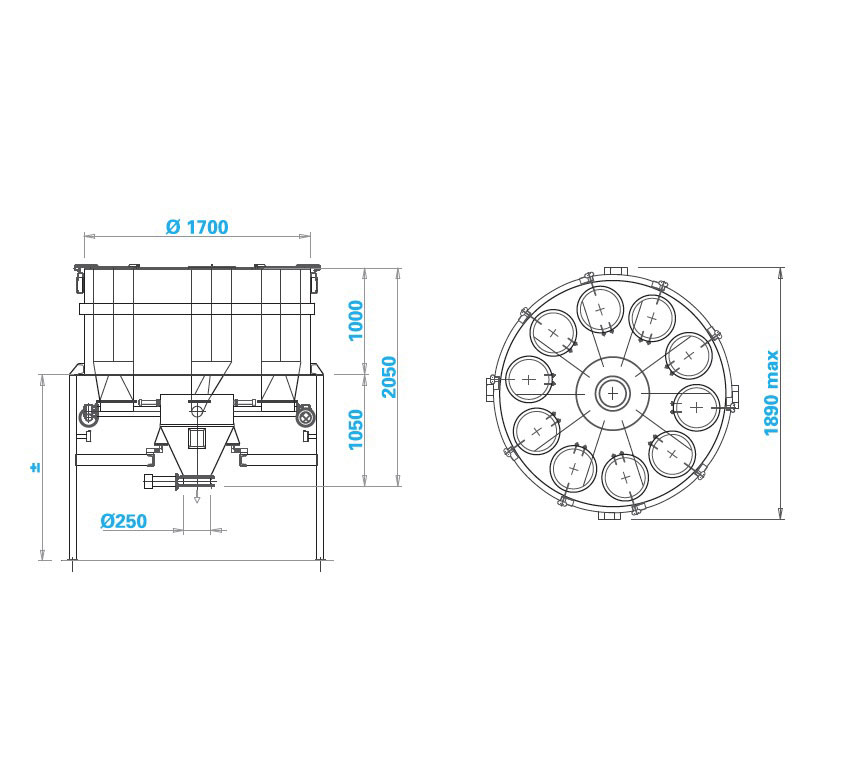

- Cylindrical cells constructed from AISI 304 or AISI 316 stainless steel which prevents corrosion. A range of models is available with 10, 14, or 16 cells. Each cell has a capacity of 60 litres.

- Extraction system from cells is achieved by screw extractors, equipped with equipment for the extraction of difficult materials, AISI 304 / AISI 316 stainless steel construction to prevent corrosion.

- Load-cell scales, featuring high precision and minimum tolerances.

- Pneumatic conveyors enable product handling, complete with cyclone filters, rotary valves, electric fans or compressors, and silencers.

- Reinforced curves to prevent wear, and lines designed to avoid any pollution.

MANUAL LOADING SYSTEM:

- Mobile suction arm to ensure the operator’s health when unloading the bag.

- System with barcode and electromagnetic locks remotely connected to control the opening of the selected cell.

Category

Additives and premix dosing systemDownload Documentation

You may interest:

Premix dosing system

View machineDo you want more information?

If you need more details for the machine Micro ingredient dosing system do not exist, fill out this form one of our operators will contact you to give you all the assistance you need.