Rotary Cooler

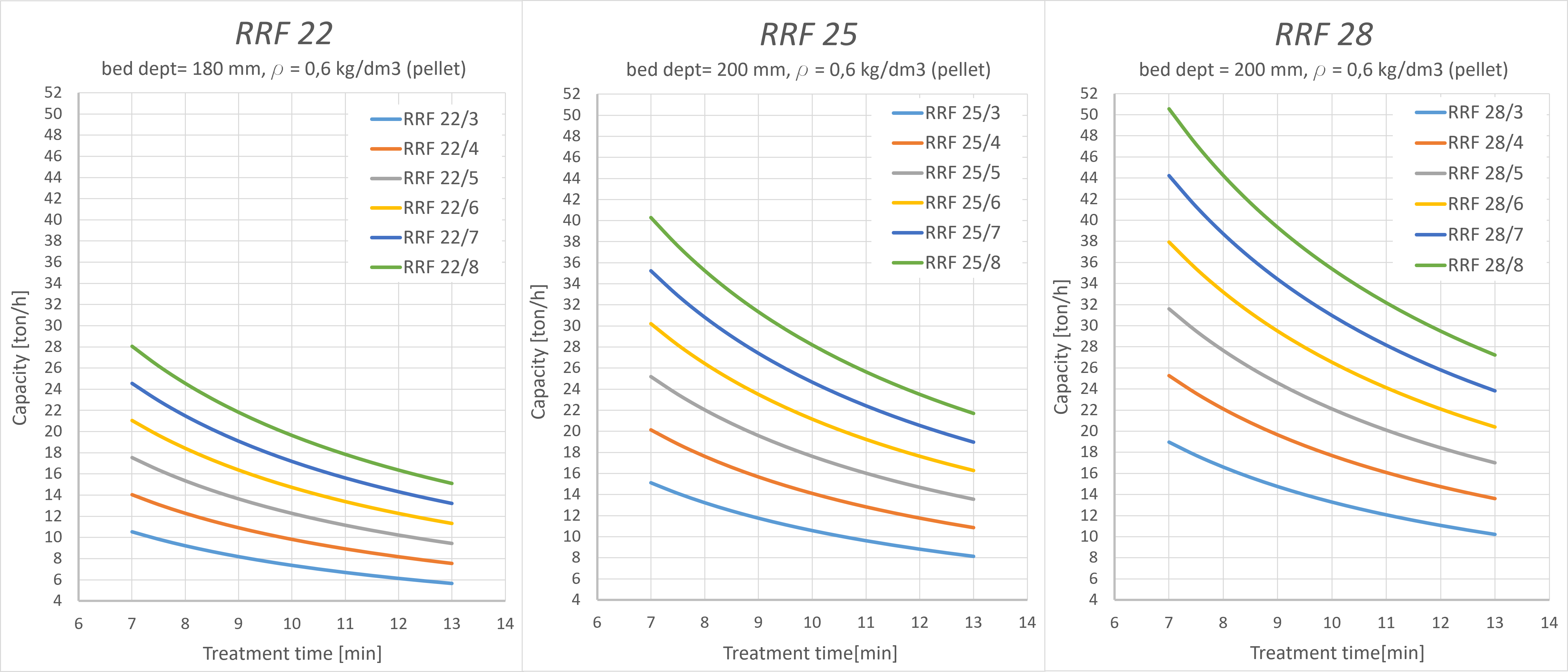

The RRF rotary cooler is used for cooling flour, pellets or flakes.

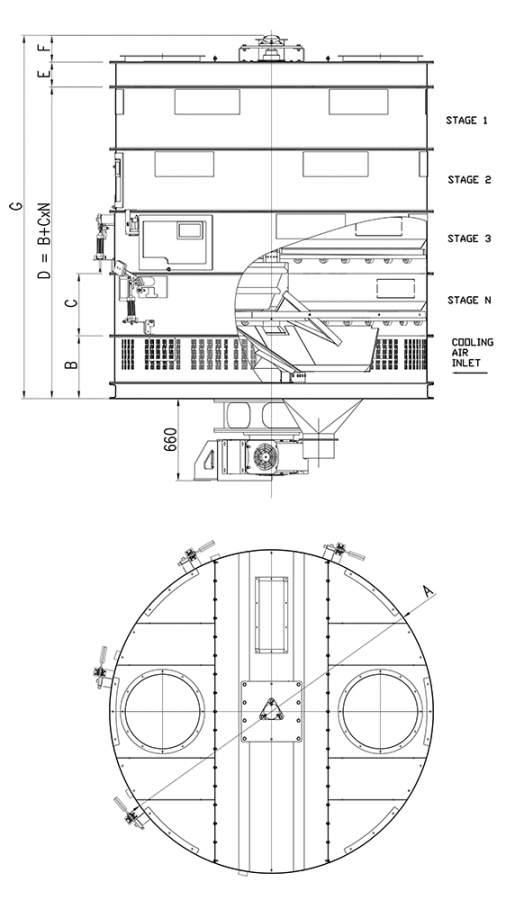

In the feed industry, it is widely used in the pelleting lines to cool the pellets. Thanks to their simple and rational design and robust construction, our modular rotary coolers are characterised by a high degree of reliability and efficiency. In small installation spaces, they ensure optimal product handling in a short time.